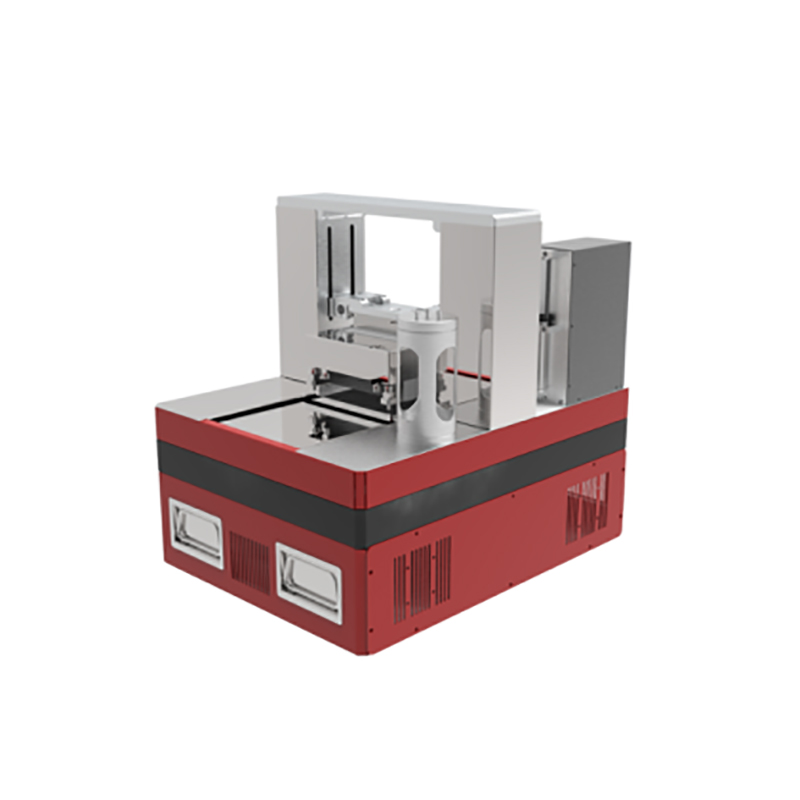

Small desktop laboratory slit coating machine

adjustable ipad stand, tablet stand holders.

Desktop slit coating machine

Specially designed for R&D and pre production environments

Coating width ≤ 220mm

1. The base adopts a marble integrated design scheme, which ensures stable coating of the entire base platform and high precision of the sample stage.

2. Adopting a dual Z-axis design: lifting the blade head through the dual Z-axis ensures long-term coating stability and blade parallelism.

3. Adopting high-precision automatic tool alignment method: easy to operate, high precision, and can avoid tool collision.

4. Injection pump: capable of 5-stage program linkage, ensuring maximum reduction of the final thick edge effect

5. Wind knife: equipped with adjustable scale/angle/height, can be placed at a distance of 1mm-2mm from the coating head, providing more stable air flow and ensuring film surface crystallization, so that the wind knife can blow the entire coating area.

6. Professionalism: Fluid simulation design of cavities, customized cutting heads.

7. Factory standard: Strictly implement in factory quality control, and maintain 2000 operation tests before the equipment leaves the factory.

Process indicators

| Slit coating machine host |

Complete coating host Including: vacuum adsorption, contact points Tool alignment device, blade head, gasket |

Distance between mold head and platform | Fine tuning adjustable range: 0-10mm Unit adjustment accuracy: 0.001mm Coarse adjustable range: 0-50mm |

| Substrate | Rigid substrate/flexible substrate | Syringe capacity | 10ml |

| substrate thickness | 0.05-10mm | Automatic mode extraction quantity | 0.1-10m |

| Coating platform area | 200mm*300mm | Blade height | 20-1000um |

| Width of coating head | 100mm/200mm | Blade levelness | ±3um |

| Dry film thickness of coating | 0.05-20um | Platform flatness | ±3um |

| Viscosity | 0-20000cps | supply voltage | 1φAC220V、50HZ |

| Solid Content | 1-75% | Blade slit width | 0.05/0.08/0.1mm(determined by the thickness of the gasket) |

| coating speed | 0.002-200mm/s | Fixed base station | by suction |

| Discharge speed | 0.1-40mL/min | Base station configuration | In situ heating function, air knife, filter, automatic cleaning device |