Products

-

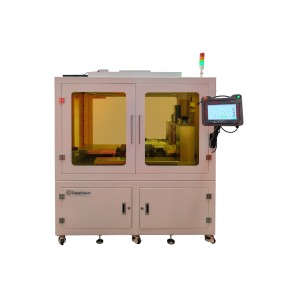

Large scale – floor standing mass production machine

Jiangsu Dita Magnesium Technology Co., Ltd. provides two solutions for the narrow seam coating field. 1. Small desktop laboratory slit coating machine. 2. Large floor type pilot line and mass production line slit coating machine.

-

VDT-6060

Substrate size: 300mm-1200mm

VCD cavity volume: 400mm * 400mm/700mm * 700mm/700mm * 1200mm/1300mm * 2500mm (others can be customized)

Vacuum pumping capacity: indicator from 10 seconds to 100pa; 30 seconds to 10pa

VCD cavity cover opening method: The cylinder automatically lifts the cover plate, and the PTFE pin automatically lifts the glass plate

Control mode: Vacuum gauge display or PLC touch screen control

Structure: Integrated structure (with built-in vacuum pump) or split structure (with external vacuum pump)

Inner box material: SUS304 # stainless steel

Outer box material: SECC steel plate advanced baking paint treatment

-

Automated Slot die high-precision slit coating

Light source part

① Use a 200W high brightness LED light source.

② An air cooling and water cooling dual cooling system using adjustable fans.

③ The system is equipped with a safe and adjustable DC power supply.

④ The power supply adopts a constant illumination LED light source, which has a long lifespan and stable light intensity.

-

Perovskite battery cyclic exposure testing system

The cyclic exposure testing system for perovskite cells can simulate the damage caused by changes in full spectrum sunlight, testing temperature, and humidity, and can reproduce the aging effect of outdoor exposure for months or even years within a few days or weeks. It can provide corresponding environmental simulation and accelerated testing for scientific research, product development, and quality control.

-

High precision ultrasonic spraying machine

The nozzle section utilizes ultrasonic high-frequency oscillation to atomize the liquid into uniform micro and nanoscale particles, reducing the requirement for nozzle aperture and reducing the risk of nozzle blockage.

-

VDT-4040

The purpose of vacuum drying VCD is to remove moisture and retain sample components by evaporating the water in the sample under vacuum conditions. This method is commonly used in fields such as food, medicine, cosmetics, and biochemical products, which can effectively extend the storage time of samples and maintain their quality. During the manufacturing process, vacuum drying can also be used to remove solvents, moisture, gases, etc., resulting in purer substances.

-

Small desktop laboratory slit coating machine

Jiangsu Dita Magnesium Technology Co., Ltd., as a company specializing in producing high viscosity and ultra-thin thickness slit coating machines, has been working in the high-end instrument and equipment industry mainly focused on slit coating machines for 16 years. The high viscosity ultra-thin thickness slit coating machine provided by the company has been continuously updated and iterated over the years, and is now the fourth generation product. The slit coating machine developed by Jiangsu Dita Magnesium has the characteristics of good film uniformity, strong controllability, wide range of applicable coating viscosity, fast coating speed, and the ability to produce large area coatings.