High precision ultrasonic spraying machine

adjustable ipad stand, tablet stand holders.

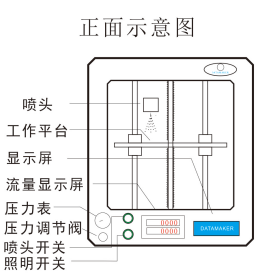

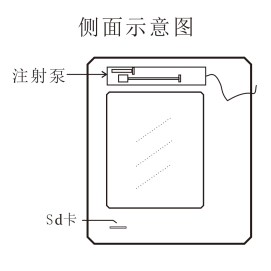

Overall design plan (if there are slight differences in the physical product, it will result in equipment upgrade)

Figure 3 Introduction to Host Structure

Figure 2 Front view of the physical object

2.1.1 The nozzle part uses high-frequency ultrasonic oscillation to atomize the liquid into uniform micro nano particles, reducing the requirement for nozzle aperture and minimizing the risk of nozzle blockage.

2.1.2 The system provides multi-level adjustable ultrasonic power, which can improve the uniformity of liquid particle distribution and further improve the uniformity of the sprayed coating.

2.1.3 High precision ultrasonic nozzles can achieve extremely low and stable flow rates, allowing for minimal loading on the substrate to obtain thinner thin film coatings.

2.1.4 The ultrasonic nozzle has no pressure effect on the liquid, and uses a high-precision metering pump to control the flow rate of the atomized coating liquid, thereby achieving high-precision spray flow control.

2.1.5 High precision polypropylene or polyethylene made conveying pumps, coupled with microchannel design of ultrasonic nozzles, can achieve a control accuracy of microliters per second as a whole, in order to ensure that the system has good control ability of the loading amount on the substrate per unit time.

2.1.6 Ultrasonic nozzles only require a small amount of air at the kilopascal level, and there is almost no liquid rebound or splashing during the spraying process, increasing the coating utilization rate to over 90%.

Under the action of air convection, atomized droplets usually scatter and drift in four directions. By using a guiding device to reduce air interference, directional focusing can be achieved to achieve the desired coating effect.

2.1.8 In order to ensure stable flow of liquid within the set working range, we have independently developed a liquid delivery pump, solution pipeline, nozzle delivery system, combined with a three-dimensional high-precision transmission module.

2.1.9 The 3D transmission module uses PLC as the system control core, which controls the stepper motor and stepper motor driver to achieve the movement of the nozzle in a certain 3D space under the precision manufactured light rod and synchronous belt.

2.1.10 The conveying device adjusts the movement speed of the nozzle by controlling the motor with a high-precision driver.

2.2 Software Functions

2.2.1 Visualization and control of various parameters (nozzle position, nozzle height, spray flow rate, injection speed, ultrasonic power, etc.).

2.2.2 Offline programming, simple programming, can save over 100 sets of programs at the same time, meeting different sizes and spraying processes.

Performance characteristics

• No need for manual spraying, stay away from toxic environments

• The program can be independently written to automatically complete high-precision spraying

• The effective working area of the 3D workbench is up to 300mm * 300mm, and the spraying distance is 200mm

• Accurate control of film thickness, with an accuracy of up to nanometer level

• Can be coated with various materials of different viscosities

• Good coating consistency: usually better than ± 5%

• High efficiency/material utilization rate: Material utilization rate can reach 99%

• Able to meet different needs: from research and development to pilot testing, mass production

• The process has high reliability and repeatability

• Integrated equipment, small footprint, easy to transport

Application Fields

• Thin film photovoltaic cells

• Thin film solar coating

• Perovskite solar cells

• Solar cells

• Graphene coating

• Silicon photovoltaic cells

• Fuel cell

Technical Parameter

| Basic parameters | Hardware parameters | ||

| brand | DATAMAKER | Spray area | 280 x 230 mm |

| model | CPT-Ultra-19 | Number of nozzles | 1 piece |

| application software | Notepad++ | Nozzle | 50Khz long mouth nozzle |

| Programming format | Gcode code code | Spray flow rate | (3-30)ML / min |

| program interface | Online or SD card offline | Flow accuracy | 1ul/s |

| Operation tutorial | instructions | Spray speed | ≤ 150mm/s |

| Power requirements | input AC220V 50Hz AC220V 50Hz | spraying method | Ultrasonic spraying |

| Power | 800W | air pressure | 0~0.2MPa(Adjustable) |

| Operation interface | Chinese/English | operating system | Win / Mac / Linx |

| software parameters | |||

| application software | DATAMAKER open software | Available formats | Support Notepad++editable |