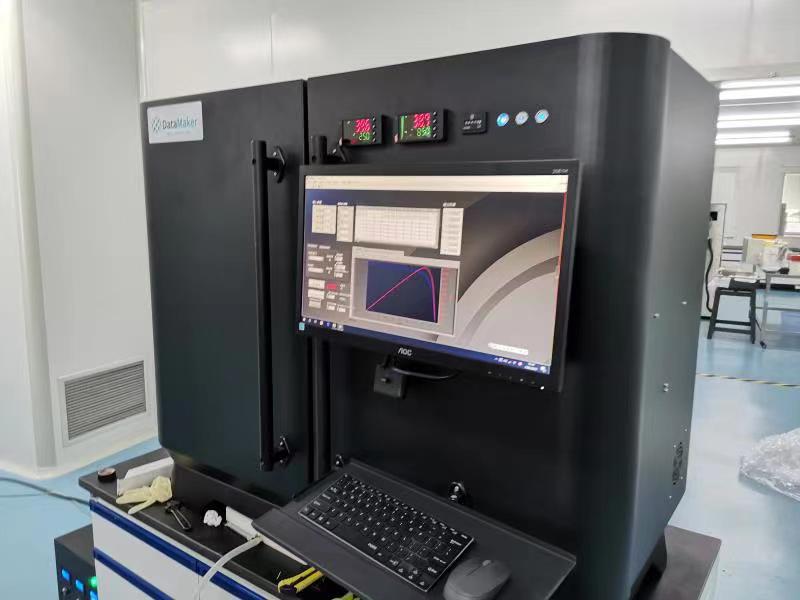

Perovskite battery cyclic exposure testing system

adjustable ipad stand, tablet stand holders.

Perovskite battery cyclic exposure testing system

The cyclic exposure testing system for perovskite cells can simulate the damage caused by changes in full spectrum sunlight, testing temperature, and humidity, and can reproduce the aging effect of outdoor exposure for months or even years within a few days or weeks. It can provide corresponding environmental simulation and accelerated testing for scientific research, product development, and quality control.

Product features and advantages

1. A very simple user interface that quickly provides results

2. Using a unique light intensity feedback system, the light intensity stability is excellent (within ± 2%) with a temperature range of 20 to 90 ° C

3. The temperature accuracy can be within ± 1 ° C and between 20 and 90 ° C. The range within ± 0.5 ° C is 25 to 60 ° C.

4. The constant temperature chamber is equipped with BNC connectors for constant temperature I-V measurement

5. The observation window allows for observation of the sample temperature chamber without opening the door.

6. Can achieve dual 85 testing, 85% humidity and 85 ℃ long-term aging testing.

7. It can achieve 15000 hours of long-term testing without the need to replace the light source

8. The bottom of the aging chamber workshop adopts a drainage groove design to prevent steam condensation and maximize the protection of the test workpiece.

Product specifications:

1、 Configuration

(1) Light source section

(2) Optical system

(3) Constant temperature chamber

(4) Measurement system

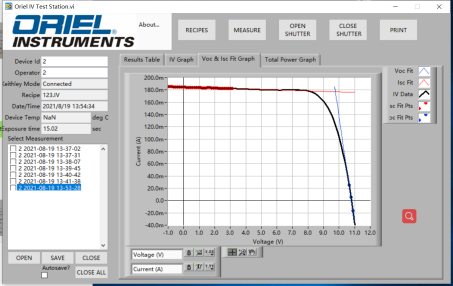

(IV Curve Chart)

2、 Specifications

(1) Light source part

① Use a 200W high brightness LED light source.

② An air cooling and water cooling dual cooling system using adjustable fans.

③ The system is equipped with a safe and adjustable DC power supply.

④ The power supply adopts a constant illumination LED light source, which has a long lifespan and stable light intensity.

(2) Optical system

① LED multiple beads, with uniform light intensity on the area.

② The irradiation area should be 300 mm × 300 mm.

③ The focal length at the exit of the exit spotlight system should be at least 110-220mm.

④ The height of the optical axis should be 50-140mm.

3、Constant temperature chamber

① Set the temperature range to 20 to 90 ° C.

② The temperature accuracy should be within the range of ± 1 ° C and within the range of 20 to 90 ° C. Within the range of ± 0.5 ° C

The range is 25 to 60 ° C.

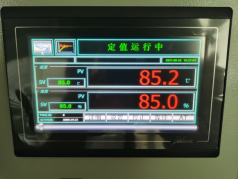

③ The temperature should be controlled and set through digital microcomputer PID control.

④ Temperature sensors should use K-type thermocouples.

⑤ The humidity measurement range should be from 0 to 85% RH.

⑥ The humidity measurement accuracy should be ± 2% (25 ° C, 0 to 80% RH).

⑦ The BNC connector panel is built-in in a constant temperature chamber.

⑧ The observation window can observe the sample constant temperature chamber without opening the door.

⑨ The sample rack/bracket should be standard configuration.

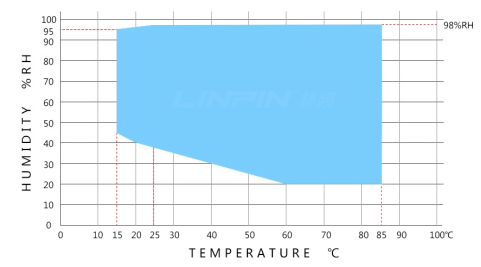

(Temperature and humidity controllable range diagram, without active humidity or thermal load)

(4) Measurement system

① Equipped with 16 sample switching relay boxes, capable of switching 16 samples.

② In the four sample switching relay boxes, when no samples are measured, three types of open circuit, short circuit, or load resistance can be selected for each sample.

③ For each of the 16 samples, the load resistance of the 4 sample switch relay box should be able to continuously change from 0 to 2000 Ω.

④ A current and voltage meter should be installed, with a current measurement range of ± 10 pA to 1 A or higher and a voltage application range of ± 1 μ V to 20 V or higher.

⑤ Time process I-V measurement software should be provided. Up to 1000 hours (60000 minutes), with a minimum of 1 minute step, it can be input for IV measurement and short-circuit current measurement at will.

⑥ The sample names and sample areas of 16 samples can be entered separately in the time process I-V measurement software.

⑦ I-V measurement software should be able to measure short-circuit current density, open-circuit voltage, maximum output, maximum power voltage, maximum power current, fill factor (FF), conversion efficiency, series resistance, parallel resistance, and set time interval.

⑧ The time process I-V measurement software can save real-time measurement data in the text during the time process measurement period, and can create an Excel file after the measurement is completed.

⑨ Schedule I-V measurement software should be in English.

⑩ A set of Note PC with Windows 10 should be provided.

Classic users:

More than ten domestic research groups, including Shanghai Jiao Tong University, Peking University, Chinese Academy of Sciences, and Shanghai Institute of Silicates.